We evaluate qualities such as hardness, chemical composition, microstructure, corrosion resistance, dimensional stability and magnetic or non-magnetic behavior. Our metal material testing allows you to validate material properties at each stage — before, during or after heat treatment.

Types of Material Testing We Offer

We provide a wide range of material testing services to support OEMs in aerospace, defense, medical, automotive and other high-performance industries. Whether you need non-destructive or destructive material testing, our metallurgical testing services adapt to your part’s needs and specifications.

Mechanical Testing

These tests provide values that measure strength, toughness and hardness. The mechanical tests we offer include tensile tests (ambient and elevated temperature), impact/Charpy testing, various hardness testing (including Rockwell & Brinell) and stress-rupture tests.

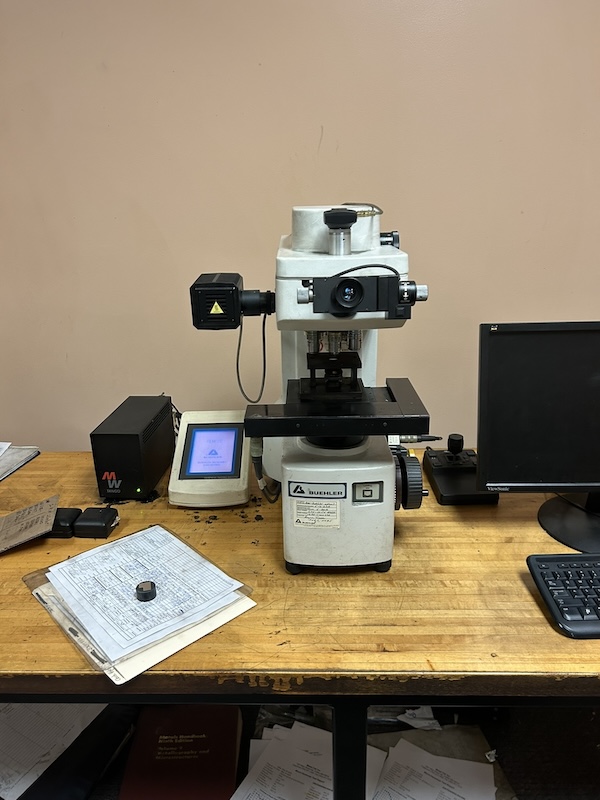

Chemical Analysis & Metallographic Testing

We analyze alloy composition via methods such as optical emission spectroscopy and X-ray fluorescence, examine phases and microstructure and verify case depth and carbon content. Metallographic analysis helps you understand grain size, inclusions and heat treat effectiveness.

Non-Destructive Testing (NDT)

NDT does not damage the part and are ideal for verifying integrity without destroying the component. Examples include magnetic particle inspection, liquid (or fluorescent) penetrant inspection, radiographic (X-ray) inspection, hydrostatic testing and positive material identification.

What Is the Difference Between Non-Destructive Testing (NDT) and Destructive Testing?

Non-destructive testing (NDT) inspects or evaluates a part without harming its structural integrity. Destructive or semi-destructive tests, including micro-hardness indentations, tensile pull tests, or sectioning, do affect or consume part of the component. Examples of NDT services we provide included magnetic particle inspection and liquid penetrant inspection. In contrast, our micro hardness and Rockwell/Brinell hardness testing methods may leave indentations on the part, making them technically destructive or minimally destructive.

Common Applications of Metal Material Testing

Accuracy and verification are critical in high-risk applications. Check out some examples of how our material testing services are employed by leading OEMs in a variety of industries:

- Aerospace — turbine engine components

- Military & Defense — armored vehicle drive shafts and structural components

- Medical — implant materials and surgical instrument components

- Automotive — high-stress hydraulic components, bearing surfaces and gear teeth

- Petrochemical & Process Equipment — pipeline welds and fittings

Benefits of Material Testing

By investing in a robust metal material testing or metallurgical testing services, OEMs gain:

- Certifiable compliance — Meet specs, alloys, hardness, microstructure and certification.

- Lower risk of failure — Early detection of defects (inclusions, cracks, wrong composition) avoids costly downstream failures or recalls

- Improved product performance — Accurate mechanical properties ensure parts behave as designed under load, temperature or corrosive environment

- Quality assurance documentation — SPC reporting, lab certificates, traceability for audits and regulatory requirements

- Cost savings over time — Less rework, fewer returns, fewer failed parts, better warranty outcomes

Considerations

Before you specify the type of metallurgical or material testing you need, keep in mind:

- Importance of the part and consequence of failure — More critical parts justify more testing with more destructive methods. Less critical parts may accept lower intensity inspection

- Turnaround time — Some destructive tests or detailed metallography take more time. NDT is often faster, but time requirements will depend on part size, preparation and testing method

- Cost vs value tradeoffs — Destructive tests can render parts unusable or require backup samples. NDT is more cost-efficient for routine inspection but may provide less data in some dimensions

- Sample preparation and size — Metallographic sections need polishing, cutting and mounting. Chemical testing needs clean surfaces. NDT requires a proper surface finish and access

Trust INCERTEC With Your Material Testing Needs

With INCERTEC’s material testing services you’re backed by:

- On-site mechanical, chemical, dimensional and NDT capabilities inherited from Metal-Tek.

- Metallographic lab resources for microstructure analysis, case depth verification, carbon content and precise hardness testing

- Robust SPC and lab reporting to support traceability, compliance and confidence

- The ability to integrate material testing with our heat treating, straightening and other processes — reducing lead time and mitigating surprises

If your OEM components require proof of material properties, compliance, or performance — INCERTEC’s material testing service has the expertise and infrastructure to deliver. Contact us today with your material specifications, required standards and desired tests to get started.