NDT LIQUID PENETRANT TESTING SERVICES ARE CERTIFIED TO MEET THESE REQUIREMENTS

*Not a complete listing of available specs. Contact us at 763-373-7533 or email us at [email protected] for review and confirmation of your specification or to request a quote

USA Specifications

NADCAP Specifications

- ASTM E1417

NON-NADCAP Specifications

- MIL-STD-6866

- MIL-STD-1907

- AMS 2175

- HS447

- PN 16.03

Mexico Specifications

NADCAP Specifications

Specifications not Supported.

NON-NADCAP Specifications

- BAC 5423

- BAC 7039

- NAS 410

NDT FLUORESCENT DYE PENETRANT TESTING

Every part has imperfections, but some are difficult, if not impossible, to see with an unaided eye. NDT liquid penetrant testing literally shines a light on the flaws that exist on the surface and within a metal component. Sometimes these flaws are purely cosmetic, but others may affect the integrity of the part.

-

Surface Cracks

-

Elongated Indications

-

Lack of Fusion

-

Shatter Cracks

-

Laminations

-

Cold Shuts

-

Porosity

-

Inclusions

-

Seams

-

Shrinks

-

Laps

-

Aluminum

-

Brass

-

Copper

-

Steel

-

Stainless Steel

FLUORESCENT LIQUID PENETRANT TESTING PROCEDURE

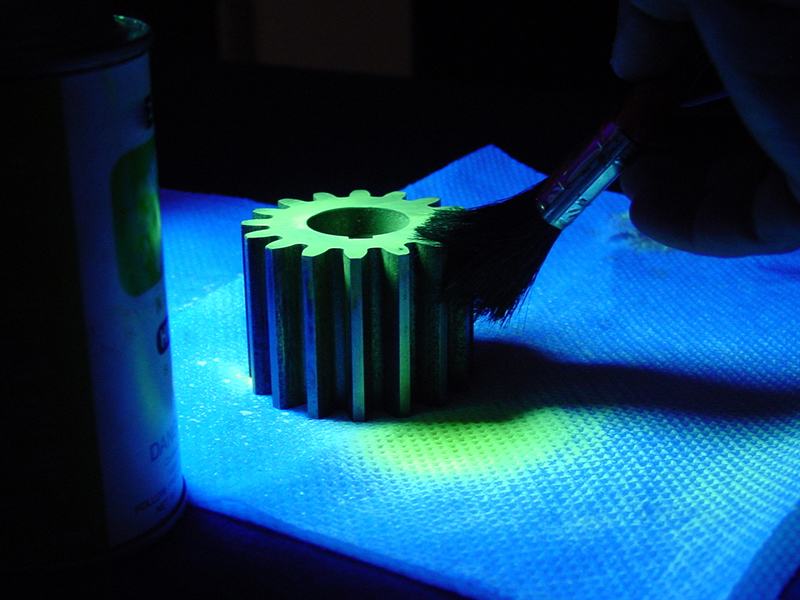

Liquid penetrant testing is one of the oldest non-destructive testing methods, and it is also one of the most effective. Fluorescent dye penetrant testing standards vary, but for the most part incorporate a similar inspection procedure. Fluorescent materials exhibit a natural glow when exposed to ultraviolet light and we take advantage of this property when testing the integrity of your part. Read more about the benefits of utilizing fluorescent dye penetrant testing.

WE TAKE A DETAIL-ORIENTED APPROACH TO FLUORESCENT PENETRANT INSPECTIONS

Cleaning: We remove any dust, debris or other particles that may fill a flaw in the material or incorrectly appear to be a flaw.

Applying penetrant: We apply the fluorescent penetrant and wait for it to sink into flaws or defects in the part. It takes longer for the penetrant to fill smaller flaws in the material than large cracks or defects.

Removing excess penetrant: We carefully remove the fluorescent material around the part, leaving only the penetrant that has entered flaws in the material behind.

Applying developer: We apply a developer material that contrasts with the fluorescent dye to the surface of the part. This material causes the fluorescent material to bleed, making it more visible for inspection.

UV-light inspection: We use a UV light to examine the surface of the part. We choose a brightness that will make the fluorescent material instantly recognizable, and mark the areas of the part that show any signs of defects.

Cleaning: Once the inspection is complete, we clean the part. If there are no defects, it is ready to be shipped to you. Flawed parts will either be fixed or discarded.