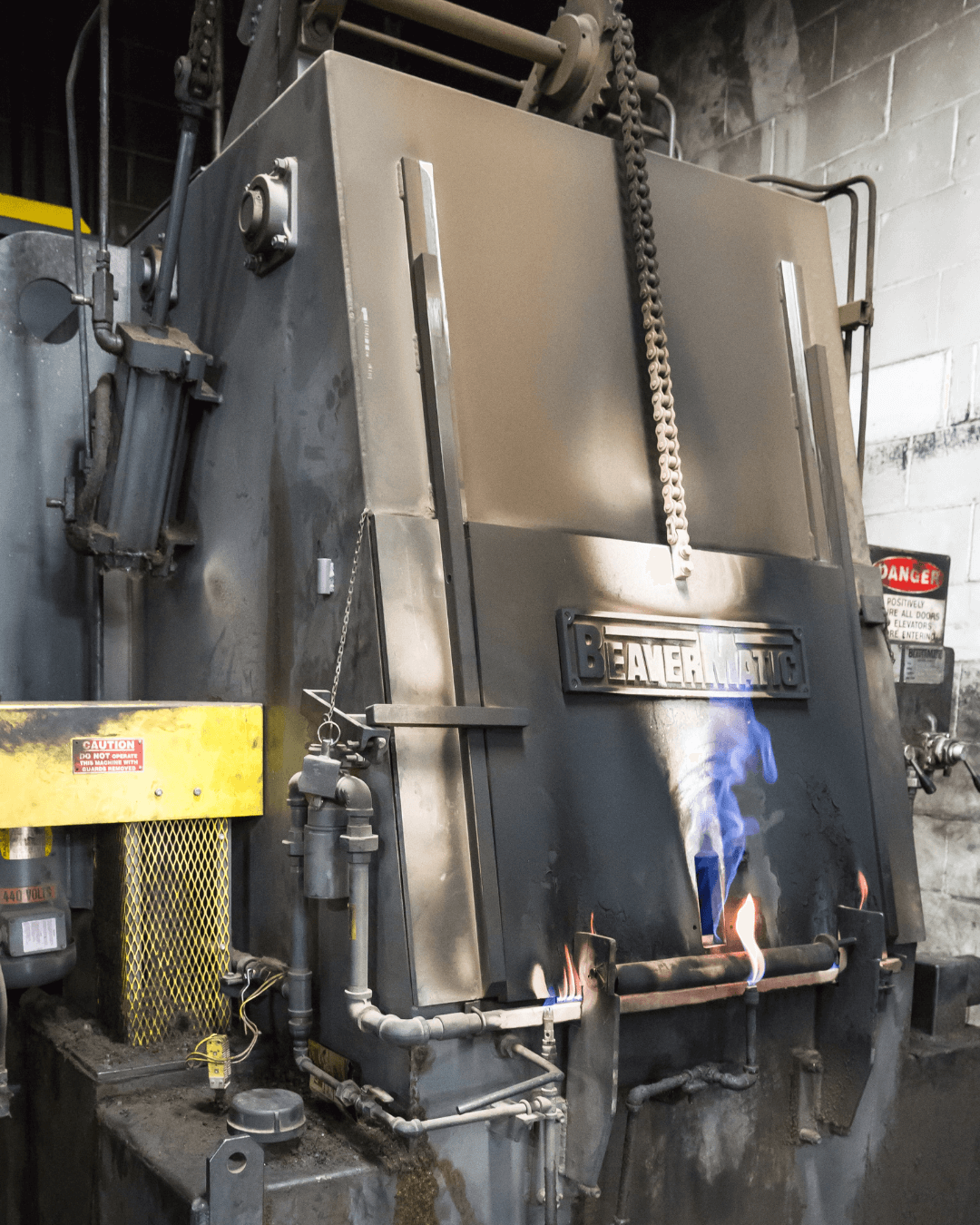

OIL HARDENING STEEL HEAT TREATING CAPABILITIES

By carefully controlling a few variables, oil hardening is able to accomplish a number of heat treatment processes including:

- Carburizing

- Carbon Nitriding

- Through Hardening

- Carburize Only

PROPERTIES

Neutral hardening through oil quenching has a number of advantages over methods like water quenching, such as:

- Superior Hardness: Oil quenching results in superior hardening of the metal component, making it a good heat treating choice for metals used in applications like steel tool making.

- Reduced Distortion: Unlike water-based quenchants, which can cause severe distortion, oil quenching minimizes distortion while still cooling rapidly.

- Enhanced Uniformity: The process ensures a more uniform microstructure, leading to consistent material properties.

- Minimized Risk of Cracking: Oil quenching reduces the risk of cracking during the cooling process.

- Adjustable Properties: Oils can be easily modified with additives to adjust their viscosity, temperature and other properties.

- Versatility: The ability to control oil properties makes it a versatile choice for various metalworking operations.

ACCEPTABLE BASE MATERIALS FOR OIL HARDENING

Not every metal is appropriate for oil hardening heat treatment. Some of the most common and compatible are steel and 400 series stainless steel.

APPLICABLE INDUSTRIES

INCERTEC oil hardening heat treatment services are used throughout a wide variety of industries, including the following:

- Aerospace

- Military & Defense

- Medical Devices

- Automotive

- Oil & Gas

- Electronics

- Tooling