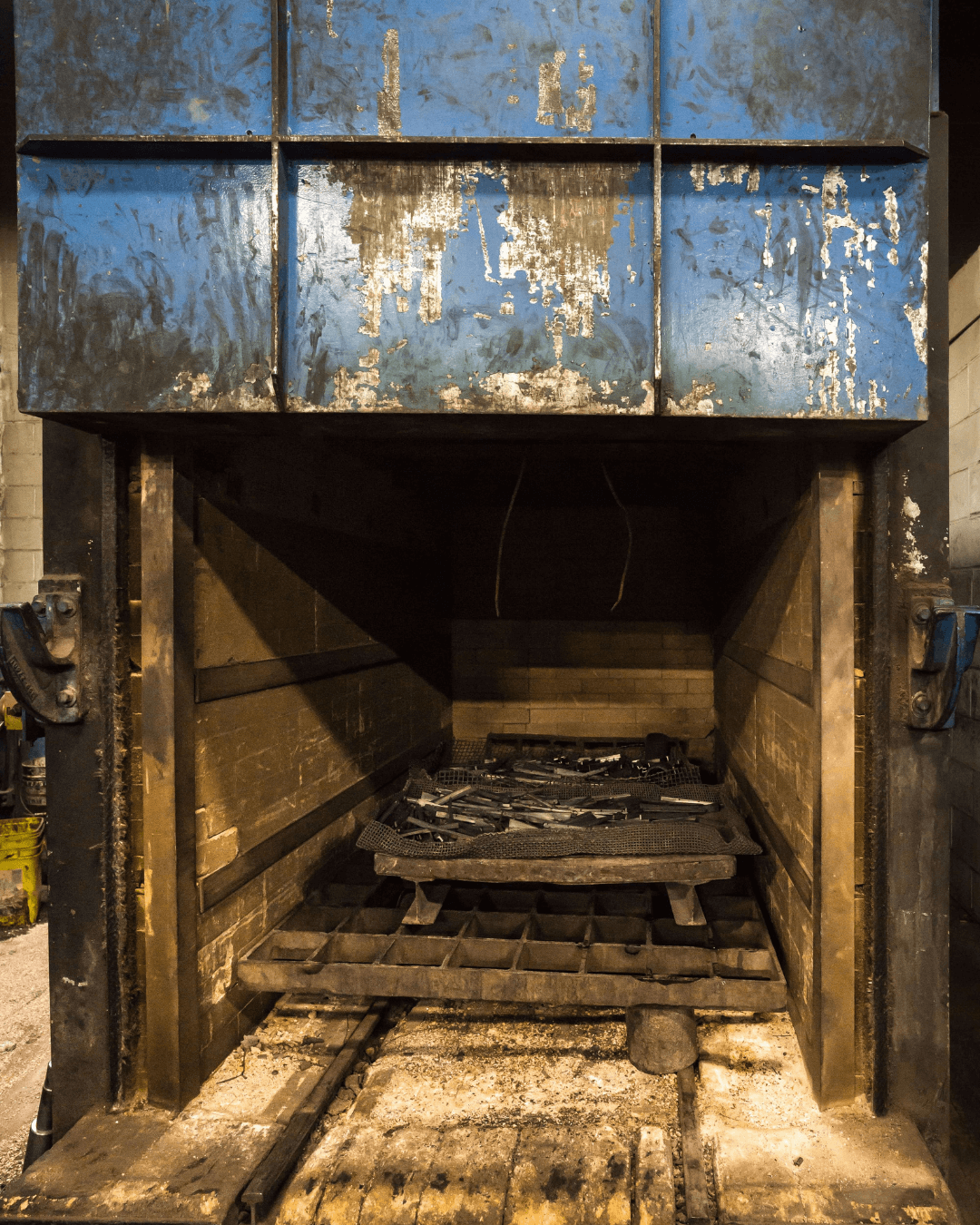

OPEN AIR HEAT TREATING

The open air heat treatment process is used to modify the properties of metal components through controlled heating and cooling in an open-air environment. This process is commonly used for normalizing, hardening, annealing and tempering, and can do everything from improving finishes to increasing toughness and more.

AIR NORMALIZING

Air normalizing is a heat treatment process where the steel part is heated into the austenitic region and then cooled in air.

- Increased Ductility: Air normalizing leads to a more uniform microstructure, resulting in an increased ability to deform plastically without breaking.

- Stress Relief: Air normalizing helps relieve internal stress induced by processes like forging, casting, machining, or welding. It allows the material’s grain structure to realign, reducing stress.

- Cost-Effective: Compared to other heat treatment processes, air normalizing is more affordable. It requires less furnace time, making it cost-effective.

- Time Efficiency: Air normalizing is quicker than some other methods, as we can switch off the furnace once the desired temperature is reached and the material has soaked for the required duration.

- Improved Surface Finish: Parts treated with air normalizing tend to have a better surface finish compared to annealed parts.

AIR HARDENING (Austenitizing)

Process used to improve the properties of metallic materials by heating them beyond critical temperature before quenching them with air.

- Increased Material Strength: Hardening results in a robust structure, enhancing the material’s strength and resistance to external stresses.

- Extended Service Life: Hardened components are more resistant, leading to an extended service life and reduced need for spare parts.

- Uniform Microstructure: Atmosphere hardening produces a more uniform microstructure, enhancing material consistency.

- Improved Hardness: The process increases the hardness of the steel component.

- Enhanced Ductility: Austenitizing makes workpieces more ductile, reducing brittleness and increasing the ability to deform without breaking.

- Dimensional Stability: It helps maintain consistent dimensions during subsequent heat treatments.

AIR ANNEALING

- Increased Ductility: Air annealing results in a more uniform microstructure, leading to an improved ability to deform plastically without breaking.

- Improved Toughness: The process enhances material toughness, making it less brittle and more resistant to fractures.

- Enhanced Machinability and Formability: Annealed materials are easier to machine and shape due to improved properties.

- Reduced Hardness: Air annealing can reduce hardness to match acceptable levels, ensuring optimal material behavior.

- Homogeneity: It improves the homogeneity of the material, resulting in consistent properties throughout.

AIR TEMPERING

- Increased Ductility: A more uniform microstructure allows for parts to better deform plastically without breaking.

- Improved Toughness: The process enhances material toughness, making it less brittle and more resistant to fractures.

- Enhanced Machinability and Formability: Annealed materials are easier to machine and shape due to improved properties.

- Reduced Hardness: Air tempering can reduce hardness to match acceptable levels, ensuring optimal material behavior.

ACCEPTABLE BASE MATERIALS FOR OPEN AIR HEAT TREATING

Some of the metals that are best suited for the open air heat treating process include:

- Steel

- SST

- Cast Iron

- Brass

- Aluminum (2024, 6061, 7075)

APPLICABLE INDUSTRIES

- Aerospace

- Military & Defense

- Medical Devices

- Automotive

- Oil & Gas

- Electronics

- Tooling