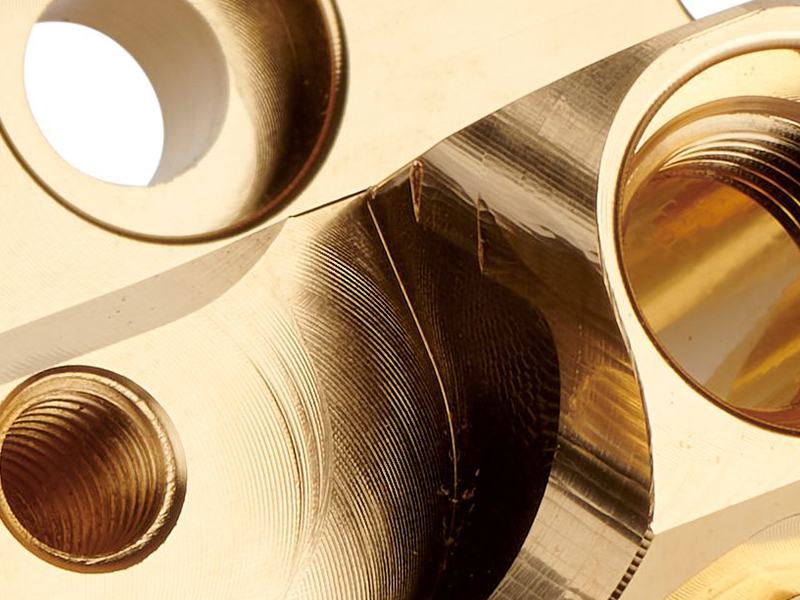

ELECTROLESS NICKEL IMMERSION GOLD (ENIG) PLATING

Electroless Nickel Immersion Gold (ENIG) plating is a surface plating process that occurs when electroless nickel plating is covered with a layer of gold. The thin layer of immersion gold is added as a protective barrier to prevent oxide from forming on the electroless nickel layer, ensuring good stability. The prevention of this chemical reaction is why ENIG plating has become widely popular for preserving the nickel layer prior to soldering.

INCERTEC has developed a specific proprietary chemistry to successfully deposit this autocatalytic coating onto typical alloys.

-

Complete Coverage for Complex Geometries

-

Uniform Plating Deposit

-

Solderable

-

Bondable

-

Alloy 42 & 52

-

Brass

-

Copper

-

Bronze

-

Steel

-

Stainless Steel

-

Kovar

-

Aluminum

-

Plastic

-

Peek

-

Ultem

-

ABS