Certified Type 2 Sulfuric Anodize Requirements

*Not a complete listing of available specs. Contact us at 763-373-7533 or email us at [email protected] for review and confirmation of your specification or to request a quote

USA Specifications

NADCAP Specifications

- AMS-A-8625

- MIL-A-8625

- AMS 2471

- AMS 2472

- 580-0008

NON-NADCAP Specifications

- ASTM B 580

- 9995902004

- 001-00187-0021

- ES10006

- PS3102

Mexico Specifications

NADCAP Specifications

- AMS-A-8625

- MIL-A-8625

- AMS 2471

- AMS 2472

NON-NADCAP Specifications

- CPS1000

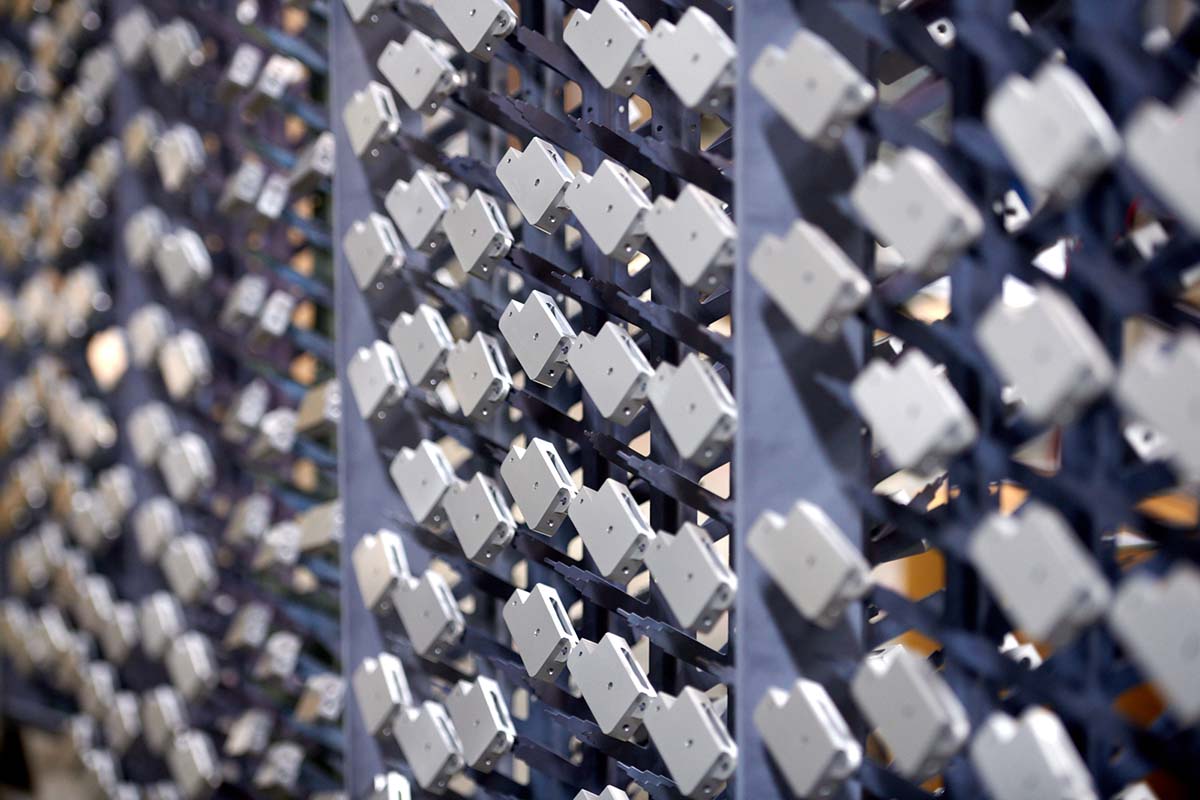

TYPE 2 SULFURIC ANODIZING

Sulfuric (Soft) anodize is the process of using electrolytic oxidation to create an aluminum oxide surface. This oxide layer is a combination of buildup on the surface of the part and penetration into the metal. Type 2 sulfuric anodize is the most common and cost-effective of the anodizing process.

-

Excellent Corrosion Resistance

-

Abrasion Resistance

-

No Chipping

-

No Peeling

-

1000 Series

-

2000 Series

-

3000 Series

-

5000 Series

-

6000 Series

-

7000 Series

-

Sand & Die Cast

-

MIC 6

-

Clear/Undyed

-

Black

-

Blue

-

Red

-

Yellow/Gold

-

Purple/Violet

-

Olive Drab Green

-

Green

-

Brown

-

Gray

-

Orange

-

Nickel Acetate

-

Sodium Dichromate

-

Hot Deionize Water

-

Duplex

-

Teflon Impregnated

-

No Seal

WHY SULFURIC ANODIZE?

Corrosion resistant, available in several color options, and extremely cost effective. Sulfuric anodize coating is a popular service for many of our customers. Sulfuric anodizing yields a coating slightly thinner and less abrasion-resistant surface than hardcoat anodizing.