Using exclusive, state-of-the-art induction systems, we deliver precision in heat treatment that strengthens critical metal components — making them more resistant to wear, fatigue and corrosion. By selectively hardening only the areas that experience the most stress, manufacturers can achieve longer-lasting performance without compromising the overall integrity of the part.

What Is Induction Hardening?

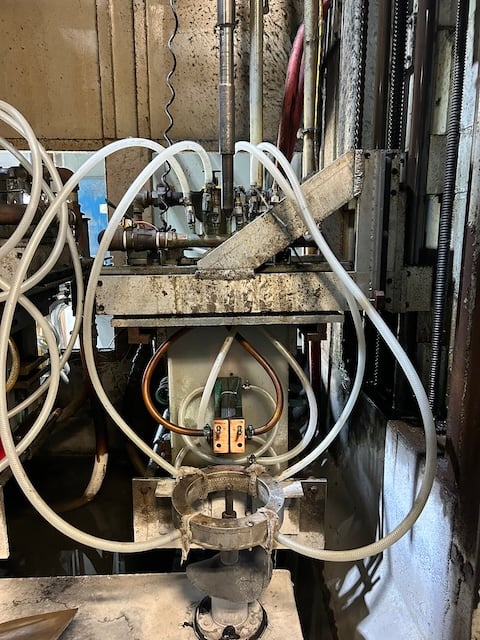

Induction hardening is a surface-level heat treatment process that uses electromagnetic induction to rapidly heat the surface of a metal component, followed by a controlled quench (cooling). This produces a hard surface (case) while maintaining a tougher, more ductile core. The key elements are:

- Frequency of the induction coil, which dictates how deeply the heat penetrates (case depth).

- The power of the induction equipment, and its ability to scan (move relative to the workpiece) or apply static (single-shot) heating to selected areas.

- A rapid quench (often water or another medium) to lock in the hard microstructure.

The frequency of our induction machines ranges from 3 to 50 kHz, allowing them to handle diameters from 3/8″ to 15″, and scanning lengths up to 70″ end to end. With power ranges of 50 to 300 kW, most OEM case depth requirements can be met reliably.

Induction Hardening vs Flame Hardening

Both induction and flame hardening are services that improve the durability of steel parts by heating and rapidly quenching the surface. The difference lies in where the heat comes from, how it is applied and the control one has over parameters:

| Feature | Induction Hardening | Flame Hardening |

|---|---|---|

| Heat source | Electromagnetic field induces heat inside the surface layer | Open flame directed onto surface |

| Precision and repeatability | Very high; microprocessor-controlled equipment ensures tight tolerances, repeatability and minimal operator variation | More variability; flame shape, operator skill and flame travel can introduce inconsistencies |

| Selectivity | Easily targets specific areas (e.g. gear teeth, shaft journals) via scanning or coil design | Less selective; depends on flame positioning and masking |

| Surface finish and distortion | Lower risk, better control, less scale or discoloration; controlled quenching reduces distortion | Higher risk of distortion, surface scaling, less precise control |

| Suitability for tight specs | Excellent, especially for aerospace and medical parts where case depth, hardness and dimension tolerances are critical | Sometimes acceptable, but often requires rework or grinding to tolerance |

Common Applications of Induction Hardening

Induction hardening is widely used in industries where strength, durability and performance under stress are non-negotiable. These include:

- Aerospace

- Automotive

- Military & Defense

- Medical Devices

- Heavy Equipment / Industrial Machinery

- Recreation All-Terrain Vehicles

Common Parts Treated With Induction Hardening

Induction hardening is usually used for parts that face cyclic loading, wear or need strong surface performance. Some examples are:

- Gears

- Shafts and axles

- Camshafts and crankshafts

- Bearings and bearing Races

- Rollers

- Hydraulic system components

Ideal Metals for Induction Hardening

- Medium- to high-carbon steels

- Alloy steels such as 4140 and 4340

- Ductile iron

- Select stainless steels with enough carbon content

Benefits of Induction Hardening

OEMs choose INCERTEC’s induction hardening because it delivers reliable, measurable improvements in performance:

- Improved Corrosion Resistance — Hardened surfaces resist degradation from exposure and wear

- Increased Fatigue Strength — Prevents cracking or failure under cyclic loading by increasing surface hardness while preserving core toughness

- Reduced Friction & Wear — The hardized surface offers improved resistance to abrasion and wear in contact areas

- Reduced Maintenance Costs — Parts last longer, downtime and replacement expenses drop

- Close Tolerance, Precise Control — Microprocessor-controlled machines provide consistency in hardness, case depth and geometry

- Quality Assurance — Dimensional inspections throughout the process and SPC (Statistical Process Control) reporting

Considerations

Before specifying induction hardening for your parts, consider:

- Part dimensions — ensure the part fits within the 70″ scanning capability and a 3/8″ – 15″ diameter range of the induction equipment

- Case depth vs hardness trade-off — deeper case may need lower frequencies or longer heating; power levels and quench design matter

- Distortion and cracking risk — rapid quenching can introduce residual stresses; proper fixturing, hardness gradients, pre-heating or tempering may be needed

- Material composition — sufficient carbon content is required for induction hardening; certain alloys require tweaking or post-treatments

Induction Hardening Services

INCERTEC’s Induction hardening services deliver surface treatment tailored to demanding OEM standards. Whether you require small batch work or high throughput, precision case depths or tight hardness ranges, our service supports both static (single-shot) and scanning induction hardening methods to meet expectations for aerospace, defense, medical and other OEMs.

Trust INCERTEC With Your Induction Hardening Needs

With decades of experience in advanced heat treatment processes, INCERTEC is uniquely positioned to deliver precision induction hardening services for the most demanding OEM applications. Whether you’re producing mission-critical components for aerospace, high-precision automotive parts or reliable medical devices, you can count on INCERTEC for the consistency, expertise and quality you need.

Ready to strengthen your components with induction hardening? Contact INCERTEC today to start your project.