CERTIFIED GOLD ELECTROPLATING REQUIREMENTS

Not a complete listing of available specs. With multiple kinds of gold plating services available, INCERTEC can meet a range of application requirements. Contact us for review and confirmation of your specifications.

USA Specifications

NADCAP Specifications

- 580-0143-000

- ASTM B488

- MIL-DTL-45204

- MIL-G-45204

- AMS 2422

NON-NADCAP Specifications

- 9902138

- 001-00187-0005

Mexico Specifications

NADCAP Specifications

- Not Certified in Mexico

NON-NADCAP Specifications

- Not Certified in Mexico

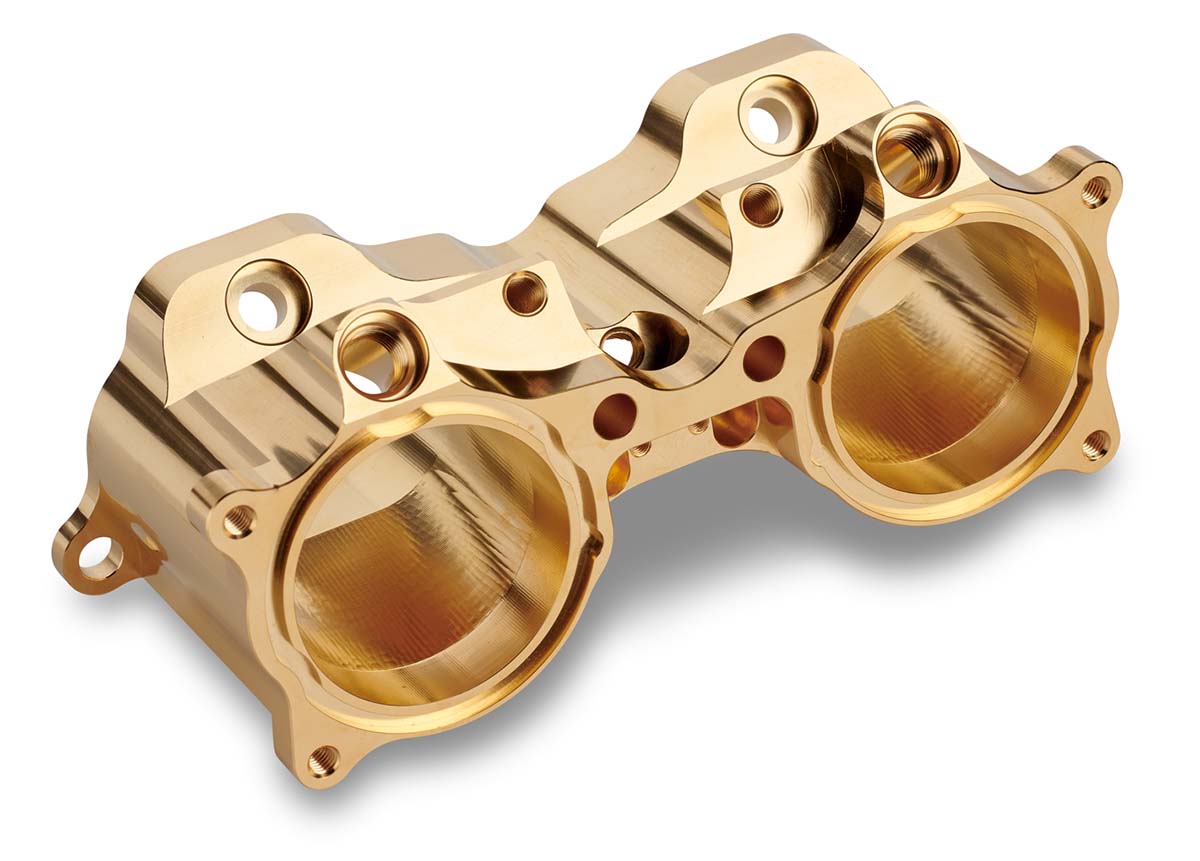

HARD GOLD ELECTROPLATING

Hard gold is ideal for parts that require more protection against abrasive deformation.

-

Corrosion Resistant

-

Abrasion Resistant

-

Electrical Conductivity

-

Thermal Conductivity

-

Radiation Reflection

-

Solderable

-

Bright

-

Aluminum

-

Brass

-

Copper

-

Bronze

-

Stainless Steel

-

Steel

-

Super Alloys

SOFT GOLD ELECTROPLATING

Soft gold is ideal for soldering and high-temperature applications as hard gold may oxidize when exposed to heat.

-

Corrosion Resistant

-

High Purity Content

-

Electrical Conductivity

-

Thermal Conductivity

-

Radiation Reflection

-

Solderable

-

Bright

-

Aluminum

-

Brass

-

Copper

-

Bronze

-

Stainless Steel

-

Steel

-

Super Alloys

ADDITIONAL GOLD PLATING SERVICES

INCERTEC offers U.S. certified gold plating on hermetic connectors and immersion gold, a layer of electroless gold over electroless nickel plating (ENIG) for improved soldering and bonding. See our capabilities and processes.

YOUR GOLD ELECTROPLATING SOLUTION

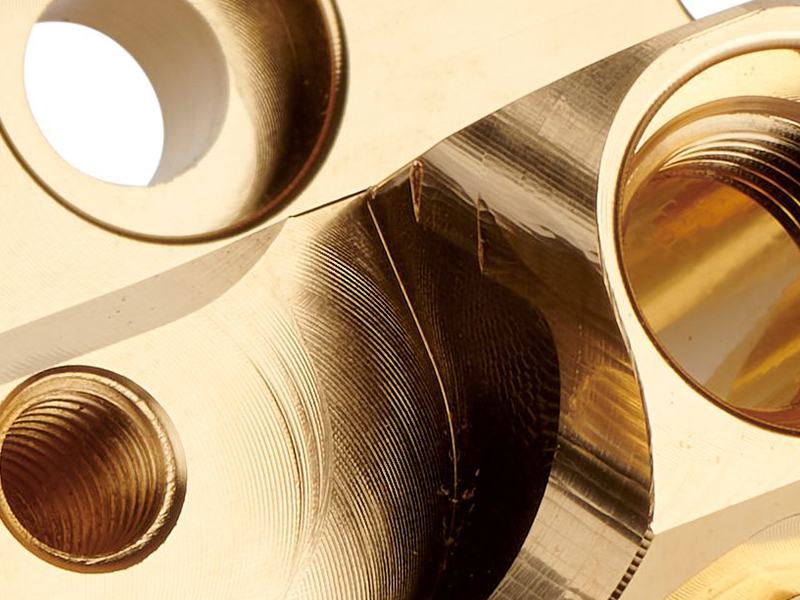

INCERTEC specializes in highly precise electrodeposited pure gold plating on contact probes and other delicate parts. We are one of few companies worldwide with the expertise and experience for plating gold on exotic substrates. Aesthetically, the luster of the gold will depend on the substrate it’s applied to. The base material will also affect the gold’s color. For example, an aluminum substrate will produce a brighter appearance than a copper substrate. Typically, the plating will mirror the incoming surface finish of the base material.

Research & Development

CERTIFIED TO MEET YOUR NEEDS

Our certifications set INCERTEC apart from other plating companies. We continually strive for innovation and technological excellence with our wide range of techniques and capabilities.

APPLICABLE INDUSTRIES