THIS SERVICE IS CERTIFIED TO MEET THESE REQUIREMENTS

*Not a complete listing of available specs. Contact us at 763-373-7533 or email us at [email protected] for review and confirmation of your specifications or to request a quote.

USA Specifications

NADCAP Specifications

Specifications not Supported.

NON-NADCAP Specifications

- ASTM B633

- AMS 2402

Mexico Specifications

NADCAP Specifications

Specifications not Supported.

NON-NADCAP Specifications

Specifications not Supported.

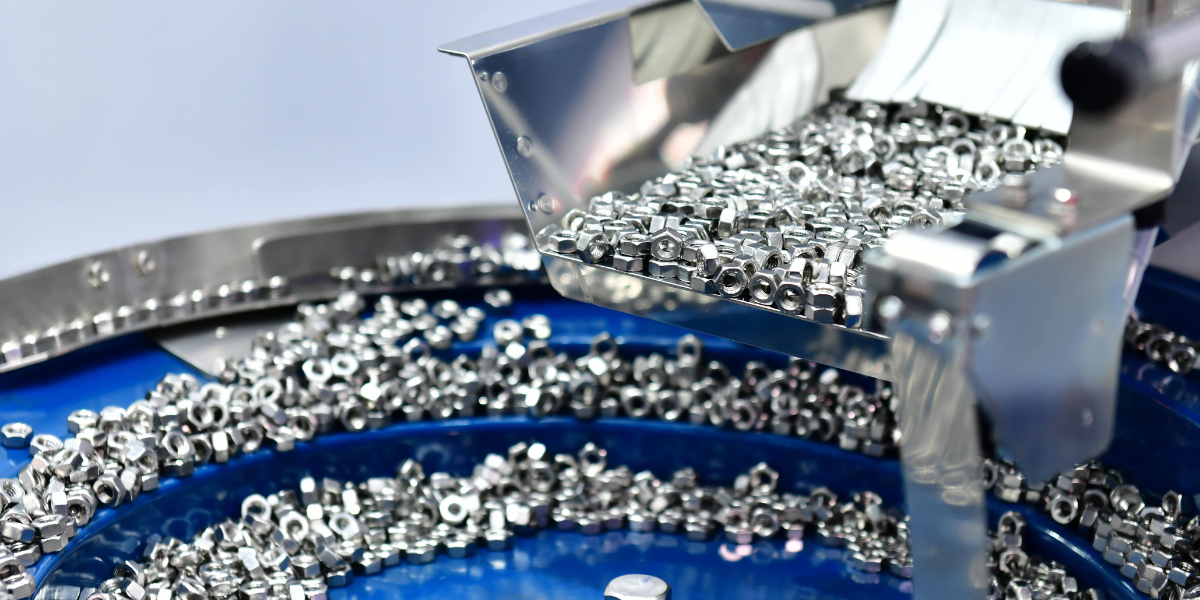

The Importance of Zinc Plating

INCERTEC’s Zinc electroplating meets ASTM B633 and AMS 2402 certifications and is crucial in industrial applications due to its ability to provide effective corrosion resistance to metal surfaces. By forming a protective layer over steel or iron components, zinc plating helps prevent rust and oxidation, thereby extending the lifespan of parts and equipment. Additionally, it enhances the aesthetic appeal of finished products by offering a bright, shiny finish and can improve the substrate’s durability and conductivity.

-

Enhanced Protection

-

Increased Ductility

-

Better Durability

-

Cost Effective

-

Easy Process

-

Aesthetic Improvements

-

Steel

-

Stainless Steel

-

Aluminum

-

Brass

-

Copper

-

Clear

-

Yellow

-

Black

ZINC PLATING FINISH COLORS

Zinc plating with different color finishes — such as black, yellow and clear Trivalent — offer a variety of different specific advantages for different applications. A black finish provides enhanced corrosion resistance and a sleek appearance, making it suitable for automotive parts and hardware. Yellow zinc plating offers robust protection against corrosion and is often used in construction and industrial settings. Clear Trivalent RoHS compliant zinc plating maintains a natural metal appearance while meeting environmental regulations, ideal for electronics and consumer goods where aesthetics and compliance are critical. Each finish color serves distinct purposes, ensuring durability, functionality and adherence to industry standards.

APPLICABLE INDUSTRIES