THIS SERVICE IS CERTIFIED TO MEET THESE REQUIREMENTS

*Not a complete listing of available specs. Contact us at 763-373-7533 or email us at [email protected] for review and confirmation of your specifications or to request a quote.

USA Specifications

NADCAP Specifications

- MIL–PRF–46010

- MIL–L–46010

NON-NADCAP Specifications

Specifications not Supported.

Mexico Specifications

NADCAP Specifications

Specifications not Supported.

NON-NADCAP Specifications

Specifications not Supported.

Mil-Spec Industrial Dry Film Lubricant

Typically made from materials like molybdenum disulfide or graphite, solid dry film lube coatings adhere to the metal substrate. Dry film lubricants offer excellent resistance to extreme temperatures, chemicals and corrosion, making them suitable for applications in aerospace, automotive and manufacturing industries where traditional liquid lubricants may not be practical or effective. They help improve efficiency, extend equipment life and reduce maintenance intervals by minimizing frictional losses and preventing metal-to-metal contact.

Meeting the Nadcap Audit Criteria for Solid Film Lubricant (AC7108/1 Rev E)

Meeting the NADCAP Audit Criteria for solid film lubricant (SFL) ensures adherence to rigorous standards in the application of dry lubricants like molybdenum disulfide or graphite. This certification guarantees that the lubricant coatings meet aerospace industry requirements for durability, friction reduction and reliability under harsh conditions. By achieving NADCAP certification, manufacturers can streamline their production processes, reduce the need for rework or quality issues related to lubrication and expedite manufacturing timelines — thereby improving overall operational efficiency and meeting strict aerospace industry demands.

-

Improved Wear Protection

-

Better Corrosion Protection

-

Low Friction

-

Increased Hardness

-

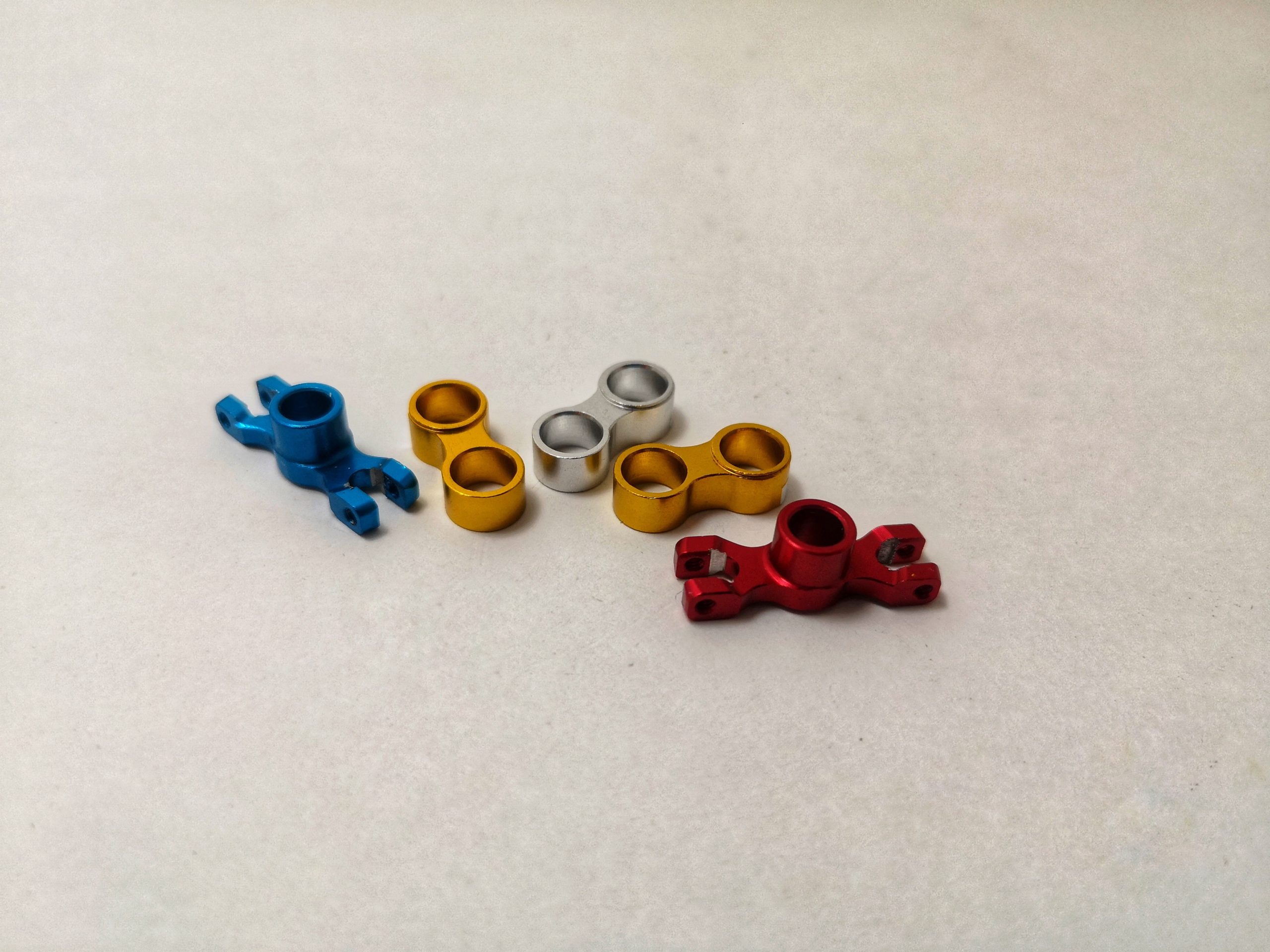

Steel

-

Stainless Steel

-

Aluminum

APPLICABLE INDUSTRIES