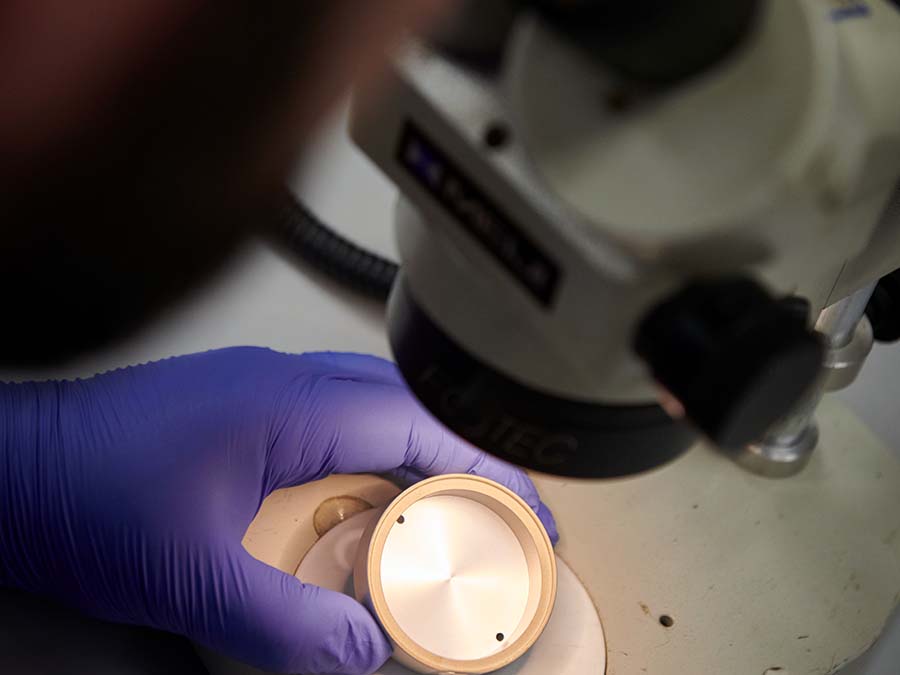

ADVANCED MATERIAL ANALYSIS

Our advanced material analysis of plated substrates set us apart in our ability to accurately and quickly inspect materials. Micro focus and proportional counter tubes are ideally suited for the inspection of parts where small structures are measured. Typical applications are measurements on pc-boards, plug contacts and other fine electrical components. The instrument is equipped with four interchangeable apertures and a programmable XY(Z) measuring stage. This makes it ideal for testing mass-production or long runs.

X-RAY ANALYSIS

Our x-ray instrument with silicon PIN detectors provides analysis results and coating thickness readings even with small concentrations and very thin coatings. Fast and precise XY(Z) measuring stage makes it ideal for automated sample measurements.

MAGNETIC INDUCTION

This is for determination of ferrite content in austenitic welded products and in duplex steel; it results in standard-conforming, non-destructive determinations. We have the ability to quickly measure ferrite content on site between 0.1 and 80% Fe.

EDDY CURRENT

This measures the hardness and strength of heat-treated materials as well as heat damage and metal fatigue. Its chief application is measuring electrical conductivity in metals such as aluminum, copper and stainless steel or non-ferrous metals.

ADDITIONAL NADCAP TESTING

- Inductive Coupled Plasma

- Atomic Absorption

- Destructive Testing (bend, cross-hatch)

- Solderability

- Taber Abrasion

- Humidity

- Porosity

- Quench

- Hardness

- Adhesive

- Tape Test

- Salt Spray

CERTIFIED TO MEET YOUR NEEDS

Our certifications set INCERTEC apart from other plating companies. We continually strive for innovation and technological excellence with our wide range of techniques and capabilities.