ELECTROPLATING PLASTIC

Electroplating plastic means moving the dissolved ions from a metal to a plastic component. By depositing the metal ions onto the plastic surface, the new part retains properties of both materials. The exterior of the part will act as a metal and can undergo additional material processes.

-

Corrosion Resistant

-

Conductivity

-

High Hardness Levels

-

Wear Protection

-

Increased Reflectivity

-

Metal Aesthetic

-

Lightweight

Ready to Make your Electroplated Plastic Needs a Reality?

Contact us today to get a free quote.

REQUEST A QUOTEPLATING PROCESS

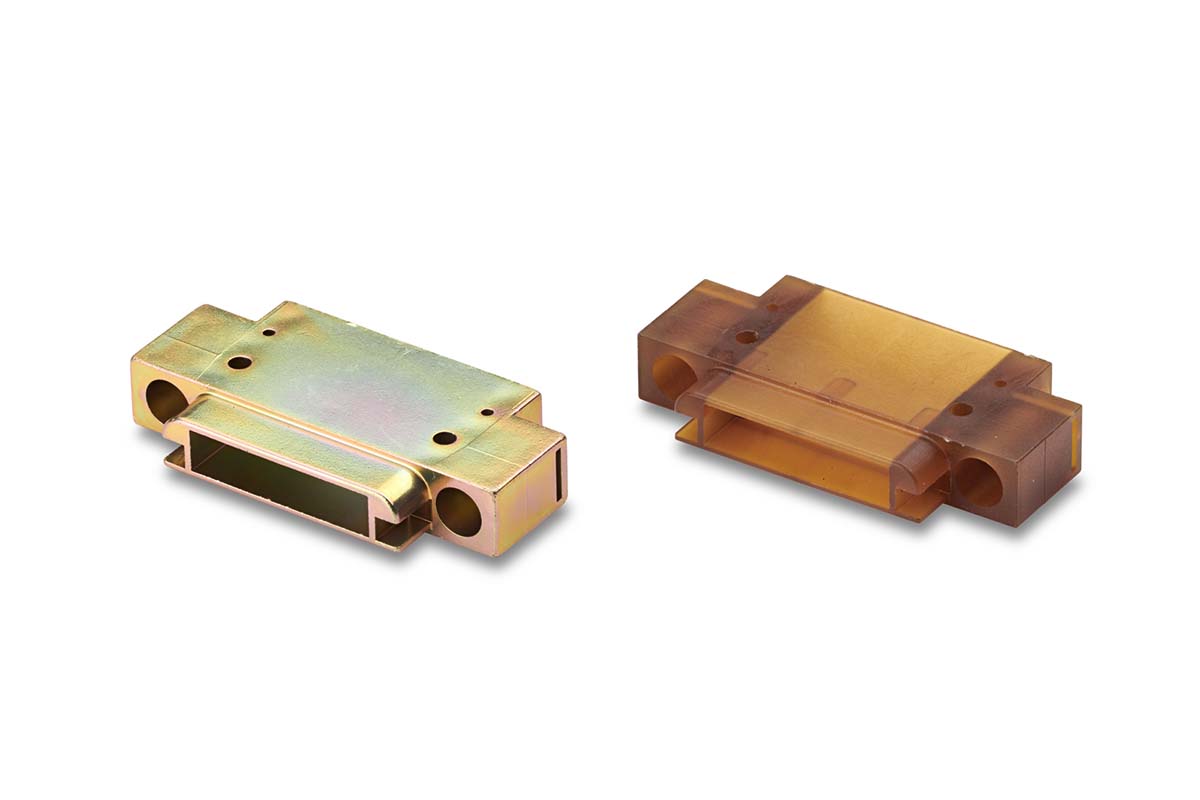

INCERTEC uses a proprietary mechanical abrasion process to help create pore sites for our proprietary chemistry to deposit a metallic layer. A process that was developed and proven out in 2011 when INCERTEC plated PBT connectors.

An electroless nickel or electroless copper is deposited onto the plastic to create the first layer to make the part conductive. This can be the final finish or alternatively, can be made a point of contact allowing the addition of electrolytic: gold, silver, nickel, cadmium, tin or zinc-nickel. Using a mechanical abrasion pretreatment process will naturally make the appearance of the plating a dull or matte finish. INCERTEC can make this bright or shiny by applying a heavy layer of electrolytic copper up to 1000 micro inches thick. This is because electrolytic copper has a self leveling property to help increase the surface finish.

Each project for plating on plastic is different. Contact us to discuss yours.

ELECTROPLATING 3D PRINTS

As 3D printers have evolved, there has been more interest in metalizing the products they produce. Reasons vary why people want to metalize 3D printed plastics, but the main two reasons are for function or cosmetics. Before we talk about the plating, you need to know what materials INCERTEC can metalize.

Acceptable Materials – Each material may respond differently to our plating process, but you want to look for a few key things if you want to plate your part.

- Fill the print as much as you can.

- Any porosity traps solution and creates a poor finish.

- Heat resistant to 200F.

- Chemical resistant.

Each project is different, contact us to talk about yours.