Mil-Spec Connector Plating Benefits

Longevity and performance are crucial for connectors used in the military and defense industries, which is why INCERTEC offers mil-spec compliant plating and coating metal finishing services for these parts. Corrosion-resistant and proven to meet the strictest specifications, our coating and plating services protect vital components in demanding conditions.

MIL-SPEC COATINGS

INCERTEC is a trusted metal finisher for the military and defense industries, providing a wide range of mil-spec coatings and plating for applications where performance is paramount and corrosion resistance is required. We protect connectors for both aircraft and land installations, including electronic connectors and wiring for communications. The finishing options we offer for mil-spec applications fall under four service categories:

- Anodization

- Plating

- Conversion Coating

- Heat Treating

Anodizing Services

There are two main mil-spec anodized coating methods: sulfuric and hardcoat anodizing. Sulfuric is one of the most popular and cost-effective anodizing methods and offers excellent corrosion resistance. Hardcoat anodizing also offers corrosion resistance while being even more durable — perfect for high-usage parts exposed to extreme conditions.

Plating Services

There are many different materials that can be used for mil-spec connector platings, depending on the desired application and properties. All plating services provide corrosion protection and are broken down in more detail below:

- Gold plating is used for conductivity and wear applications. Choose soft anodized for high-temperature and soldering applications or hard anodized for more abrasion resistance.

Learn More - Tin can be used in matte or bright finishes. Matte tin offers superior solderability, while bright tin provides a reflective finish for applications like electrical contacts.

Learn More - Tin-lead is exceptionally solderable with a darker gray finish — available in 60/40 and 90/10 co-deposited formulations.

Learn More - Cadmium with yellow or olive drab chromate is typically applied to connector shells for cosmetic value in addition to excellent corrosion resistance.

Learn More - Zinc-nickel is a more environmentally friendly alternative to cadmium plating. Combining zinc’s sacrificial coating with nickel’s ductility, strength and additional corrosion resistance can result in a finish that is superior to cadmium.

Learn More - Electrolytic sulfamate nickel can be used in many functional applications, including brazing, welding and underplating. Bright watt nickel plating is also available for more aesthetic applications.

Learn More - Electroless nickel is an extremely uniform process, best for applications with tight tolerances and underplating.

Learn More

Passivation Pretreating

Passivation is a critical pretreatment step when working with stainless steel alloys. This process removes free iron from the surface, resulting in improved protection from corrosion and rust.

Learn More About PassivationConnectors We Coat

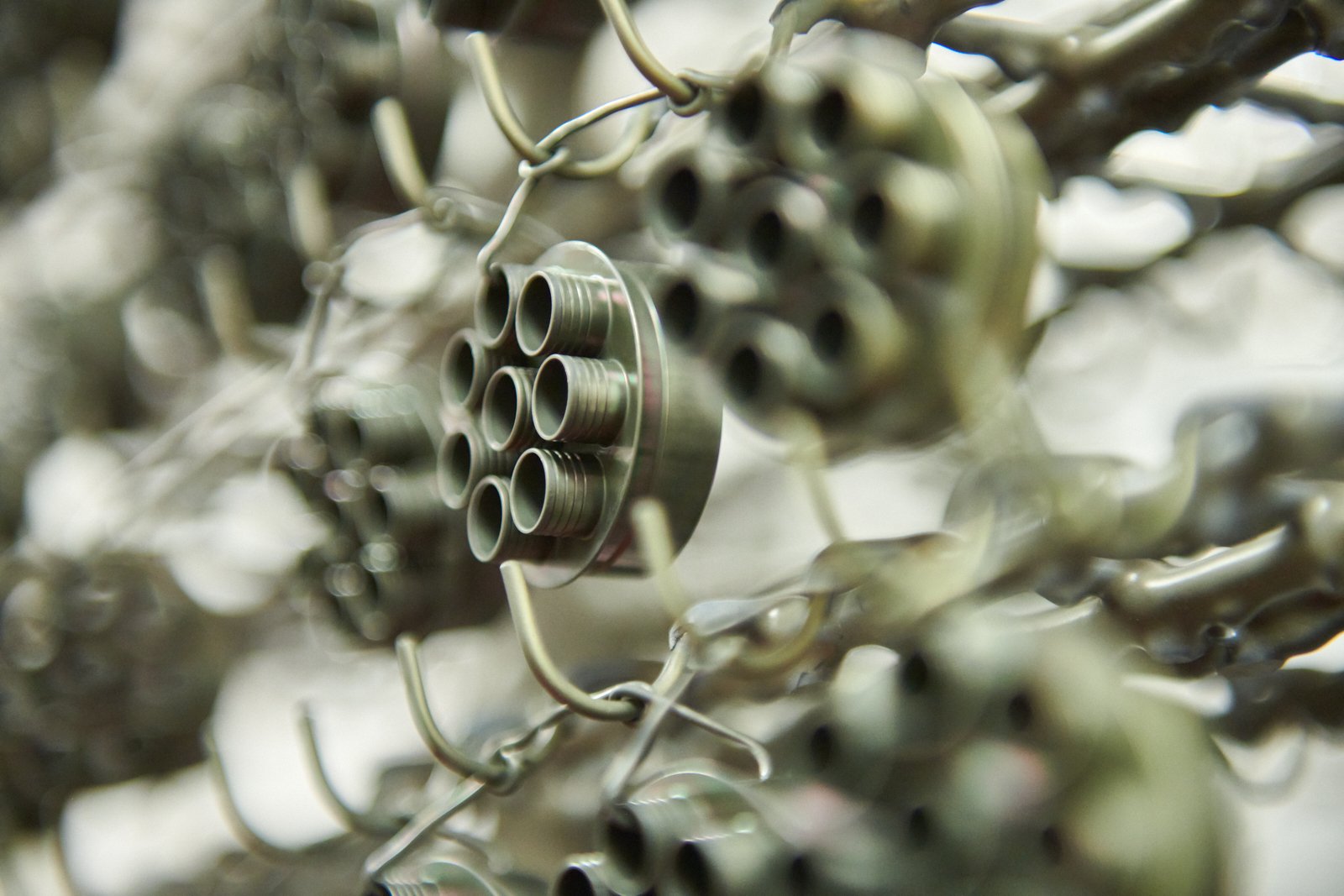

To extend the lifespan of vital military aerospace and defense connectors, mil-spec coatings are a must. INCERTEC offers coating services for the following components and connectors:

- Coaxial

- Contact pins

- Hermetic (Glass sealed)

- Micro-D

- Nanominiture (Nano)

- Round

- Square

TRACEABILITY

Our proven traceability capabilities are another reason military and defense customers trust their mil-spec coating and plating projects to INCERTEC. Our state-of-the-art barcode tracking system enables us to trace the production of parts throughout every piece of processing, including the chemistry used. We store records up to ten years electronically, so if you ever need to determine the origin of an issue, we’re able to help.

CONTACT USMeeting Military & Defense Standards

INCERTEC is adept at meeting the rigorous demands of military plating and heat treatment specifications, allowing us to provide high quality finishing for some of the largest OEMs in the industry. Explore our customer page to learn more.

OUR CUSTOMERSCERTIFIED TO MEET YOUR NEEDS

For mil-spec coatings and plating, our certifications set INCERTEC apart from other plating companies. We continually strive for innovation and technological excellence with our wide range of techniques and capabilities. Ask us about our dedicated plating line services.