The details of INCERTEC’s recent acquisition of Metal-Tek, Inc. have been featured on the Finishing & Coating website — including our expanded service list, transition plan and more. Read the Article

Benefits of the Tin Electroplating Process

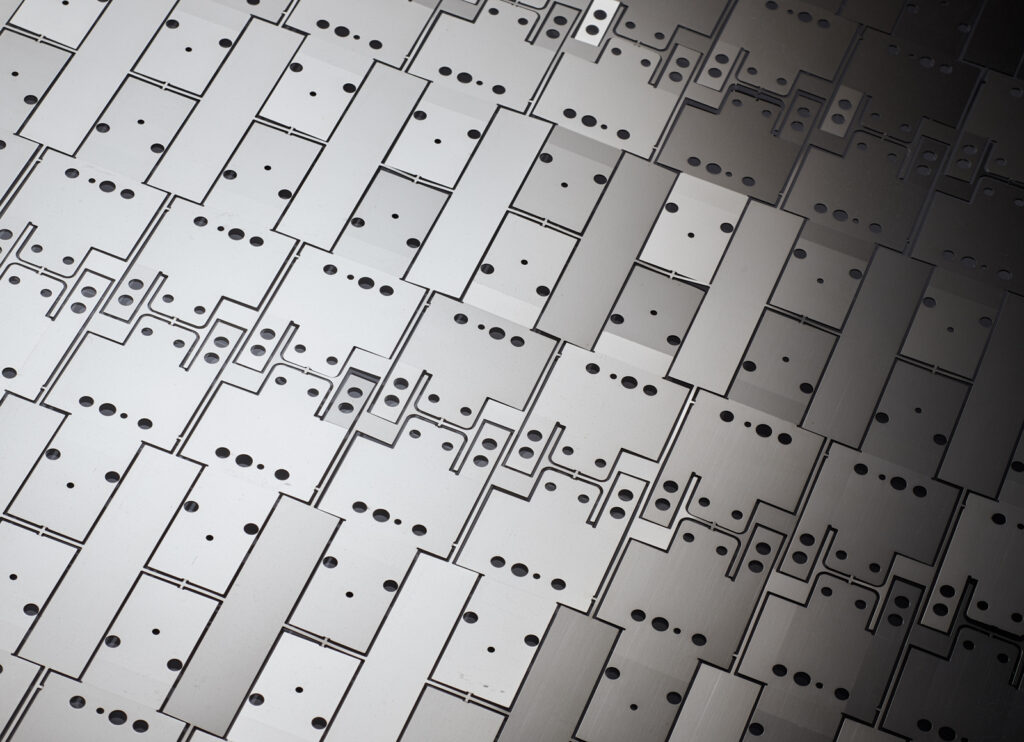

Tin is a silver-white metal that can be deposited onto both ferrous and nonferrous surfaces. Tin can also be co-deposited with bismuth or lead to alter the composition of the metal, increasing its beneficial properties. Multiple industries utilize tin electroplating for its desirable properties like high ductility and high solderability.

Read Article